← Back

CLS’s Industrial Division Develops Innovative Connected Beacons

For over 40 years, CLS has been developing satellite solutions to study and protect the planet and manage its resources sustainably. One of its key strengths? Its industrial division dedicated to connected beacons, a hub of technology and expertise serving environmental stakeholders, scientists, and marine professionals.

From fisheries monitoring to ocean research, pollution tracking, and securing merchant fleets, CLS designs and manufactures beacons tailored to the most extreme environments. Combined with reliable connectivity, multi-source data platforms, and advanced analytical tools, these devices form essential solutions for a more sustainable planet.

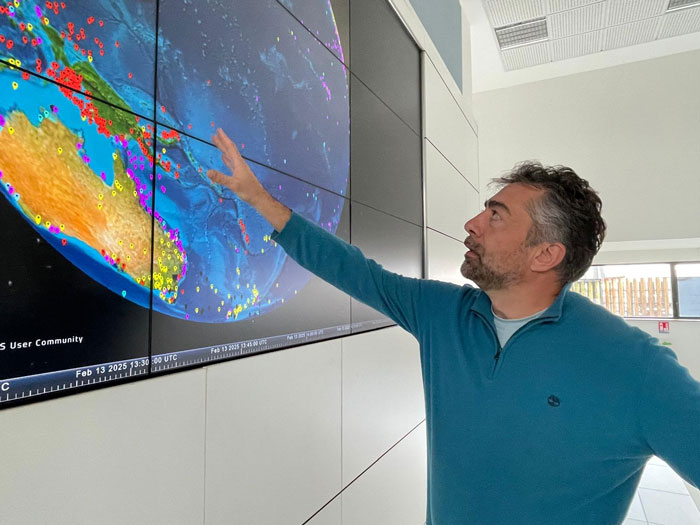

We take a closer look at this unique division with Gabriel Grebel, head of beacon development and manufacturing at CLS.

CLS’s Industrial Division Has Been Designing and Manufacturing Beacons for Over 30 Years

What makes our solutions strong and unique today?

Gabriel Grebel: CLS is, above all, a hub of comprehensive expertise that goes far beyond beacon manufacturing. We design end-to-end solutions, combining beacons – connectivity – multi-source data platforms – analytics – recommendations.

Our beacons are robust, marine-grade, and field-proven. But what truly sets us apart is the added value of our data and our ability to support our clients throughout their missions. Our solutions are essential tools for more sustainable resource management and improved environmental monitoring.

Gabriel Grebel, Head of Beacon Development and Manufacturing at CLS

CLS beacons are designed to withstand extreme environments. What are the biggest technical challenges your industrial team faces?

Gabriel Grebel: The oceans are among the most hostile environments: humidity, salinity, prolonged immersion, extreme temperature variations, mechanical shocks… Our beacons must be waterproof, UV-resistant, highly durable, and often energy autonomous.

One of the biggest challenges is also connectivity: our beacons must be able to transmit data from anywhere on the planet, relying on cutting-edge satellite technologies. Reaching the level of maturity we offer today took 40 years of engineering, dozens of models, collaborations with multiple manufacturers, and continuous improvements from one generation to the next to achieve this unique standard of product quality.

You work daily with a wide range of stakeholders—scientists, fishers, NGOs, industry players, governments… How does CLS tailor its solutions to meet each of their needs?

Gabriel Grebel: Each sector has its own specific needs, and we develop tailored solutions to match them.

For fisheries monitoring, we’ve designed the Triton beacon for industrial vessels, the Nemo for more traditional boats without onboard power systems, and the Naos to track the fishing gear itself (nets, FADs, etc). These beacons are part of a complete solution that helps regulate fishing efforts, reduce environmental impact, and support local economies. On the scientific side, our Link-it beacon allows clients to track some of the most valuable oceanographic instruments in the world—floats, buoys, and drones. This real-time tracking is crucial for ensuring the safety of their equipment and for gathering reliable, continuous data.

We’re also involved in securing merchant fleets. Our Shiploc beacons ensure vessel tracking and regulatory compliance. They also include an SSAS anti-piracy system, which we’re particularly proud of. Contributing to the safety of people at sea is a real driving force for our team. But our mission goes beyond that, our beacons also help clients combat pollution. Our Marge-T II beacon is used to track the drift of plastic, oil, or biological pollution, and even monitor the movement of sargassum blooms, which have a major impact on some coastlines, particularly in the Caribbean.

We’re also deeply committed to humanitarian efforts. We’re developing tracking and safety products for the fleets of the world’s largest aid agencies. These beacons are adapted for rugged field vehicles, including armored ones operating in extreme conditions.

What innovations are on the horizon in the field of beacons, and how is CLS anticipating future needs for a better-protected planet?

Gabriel Grebel: CLS is constantly innovating to reduce the environmental footprint of our solutions while improving their performance. We’re working on more autonomous beacons, with optimized energy solutions—solar power, improved transmission strategies, and more.

Improving onboard sensors is also key to collecting even more environmental data—temperature, salinity, pollution, and more. Hybridization is another strategic focus at the heart of our innovation. We’ve developed smarter communication systems that combine multiple technologies: satellite, terrestrial IoT, cellular, Bluetooth, and others.

What about Artificial Intelligence?

Gabriel Grebel: We’ve been pioneers in this field, our animal collars have been integrating AI for over five years now! Enhancing the use of artificial intelligence to process collected data and generate even more precise recommendations for resource conservation is something we’ve been working on for a long time.

Our innovations are already operational. For instance, they’ve enabled us to connect hundreds of reindeer in Yakutia, where endemic populations have suffered drastic declines (over 40% in just a few years). Our smart collars allow for semi-automated behavioral monitoring. The data collected is crucial for improving species conservation.

We are deploying energy-efficient AI in the field, low-consumption and adapted to remote environments.

This is a key issue for us. We’ve developed AI models specifically designed to align with our product philosophy and values.

Behind every beacon, there’s a team of passionate experts. Can you tell us about the people who make this innovation possible every day?

Gabriel Grebel: Behind every beacon, there’s a dedicated team effort. We have a passionate group made up of electronics engineers, mechanical engineers, embedded software developers, satellite communication specialists, and signal processing experts, a full range of skills that ensures uncompromising quality.

Innovation doesn’t happen in isolation. It’s built on experience, fieldwork, listening to our clients, and a tight-knit team that pushes technical boundaries every single day.

Innovation doesn’t happen in isolation. It’s built on experience, fieldwork, listening to our clients, and a tight-knit team that pushes technical boundaries every single day.

Gabriel Grebel: What drives me is the purpose behind our mission. We’re developing tools that have a direct impact on protecting the oceans, our environment, and the sustainable management of natural resources.

Every beacon we deploy is a building block in a larger structure: the effort to understand and preserve our planet. It’s a job where technology and environmental commitment come together, and that’s incredibly motivating.